Project Description

While it is Nice to Be Paid for Solving Problems,

There is Usually a Reason Nobody Has Offered to do it for Free.

Consulting contracts have come through friends or connections because I am known for solving problems

by filtering through the confusion & noise to get at what is really happening.

Malfunctioning Machinery at a New Ocean Spray Cranberry Processing Facility

Weeks Before Harvest Comes in.

The case of the malfunctioning conveyer belts, built by Haza Mechanical of Wisconsin and installed in a new Ocean Spray Cranberry plant in British Columbia. The unpleasant part was absorbing the anger and frustration of the project manager who was looking to confirm blame on the manufacturer. The site superintendent however, was more interested in solving the problem so that they could run the plant at full capacity when the cranberries started coming in from the fields within a couple weeks.

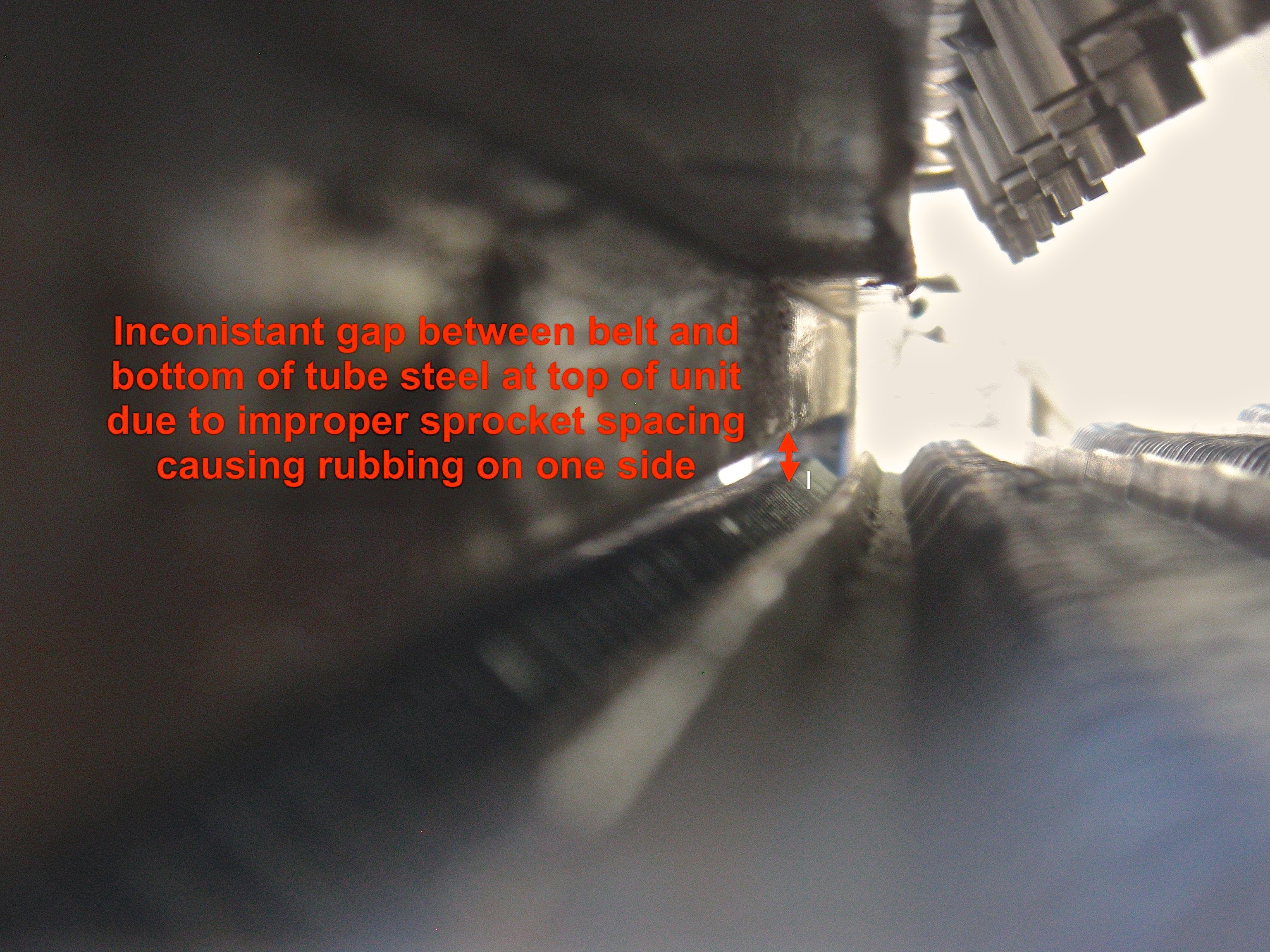

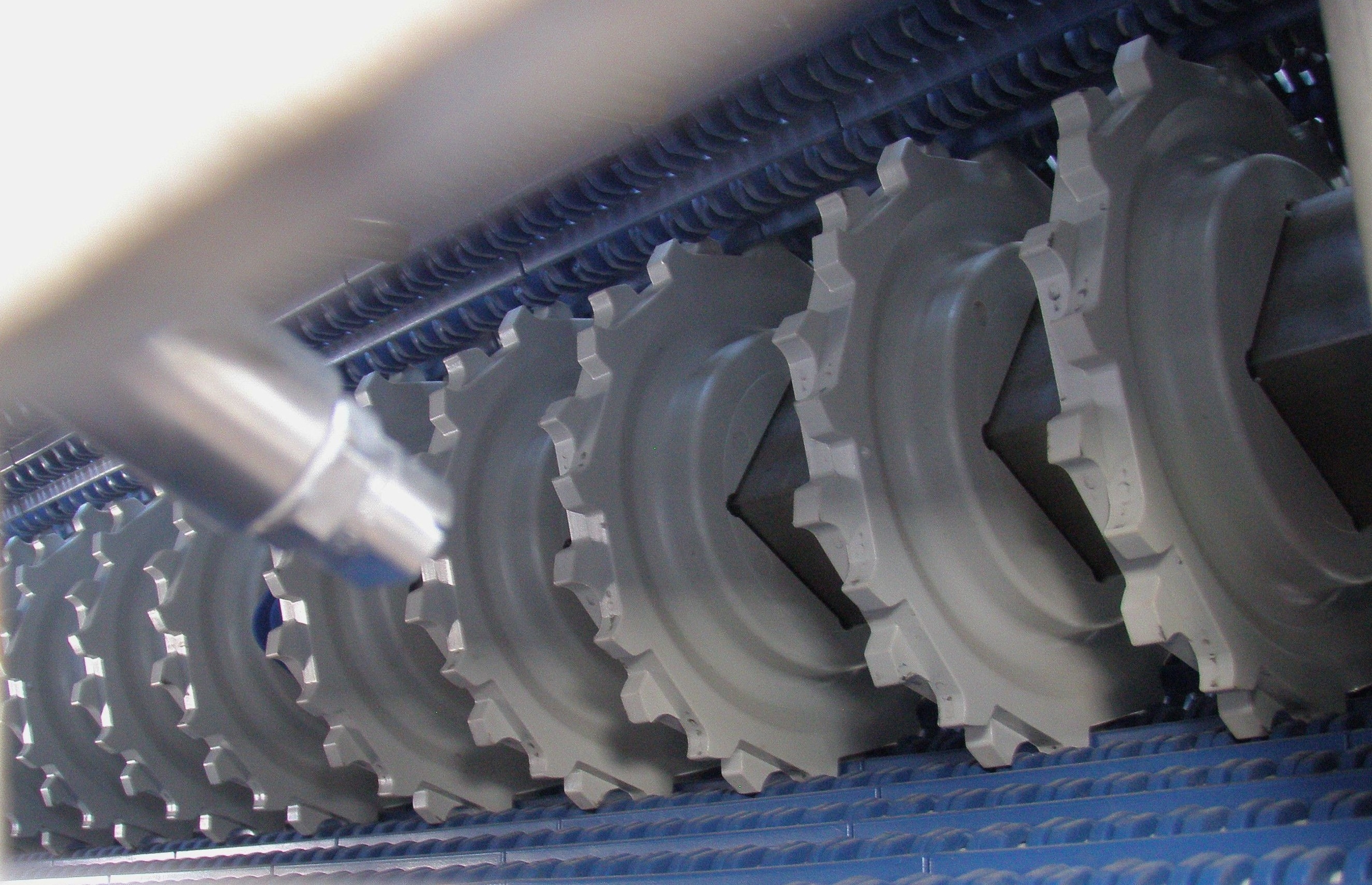

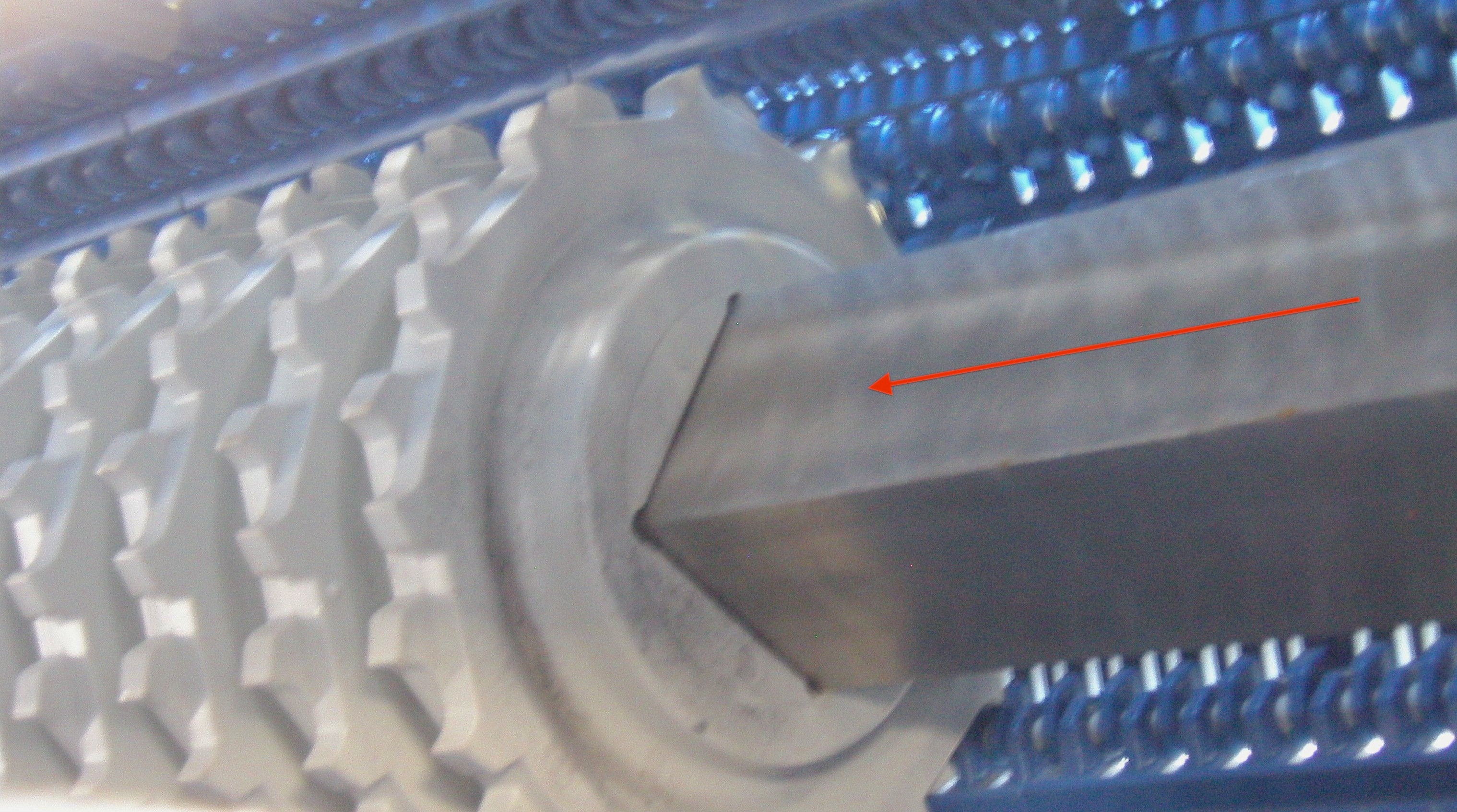

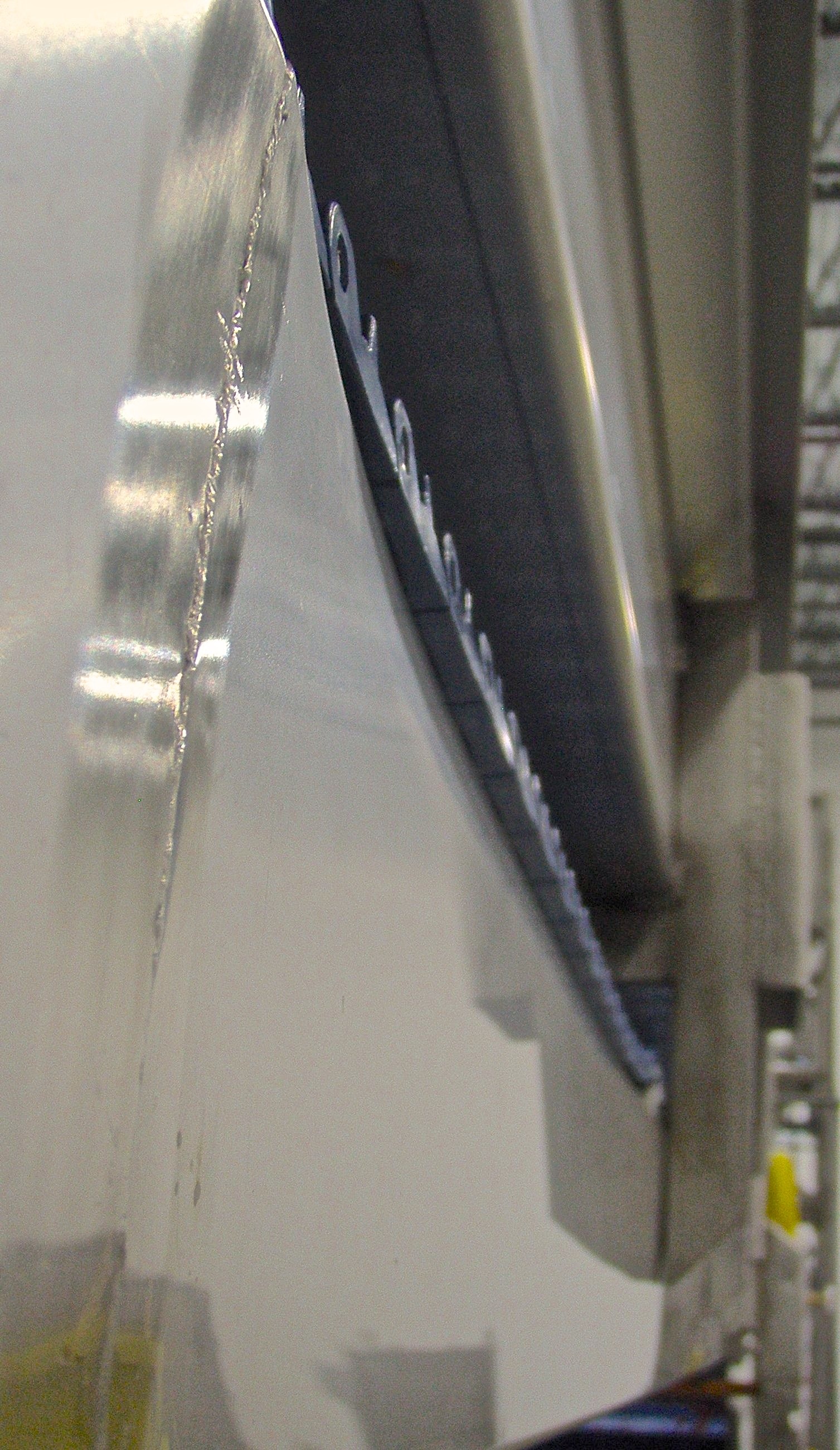

Problem: Belts Rubbing

Sprockets Pushed to one side during incorrect re-assembly by installers without informing the manufacturer or asking for direction on how to do so properly. The reasoning behind this lack of communication is unknown, but probably hinged on unrealistic deadlines and a culture of avoiding blame rather than finding solutions.

As with most situations there were enough mistakes in the process for everyone to eat a bit of humble pie and then solve the problems. In this case it primarily hinged on the equipment shifting during shipping and being improperly re-assembled, as well as miscommunication about specifications on both sides.

Getting to the causes and solutions took asking a ridiculous number of questions all around. In the end it cost the manufacturer a bit of his margin, but maintained a good relationship with the customer. Ocean Spray got their plant running in time with the onsite fixes paid for by the manufacturer as appropriate.

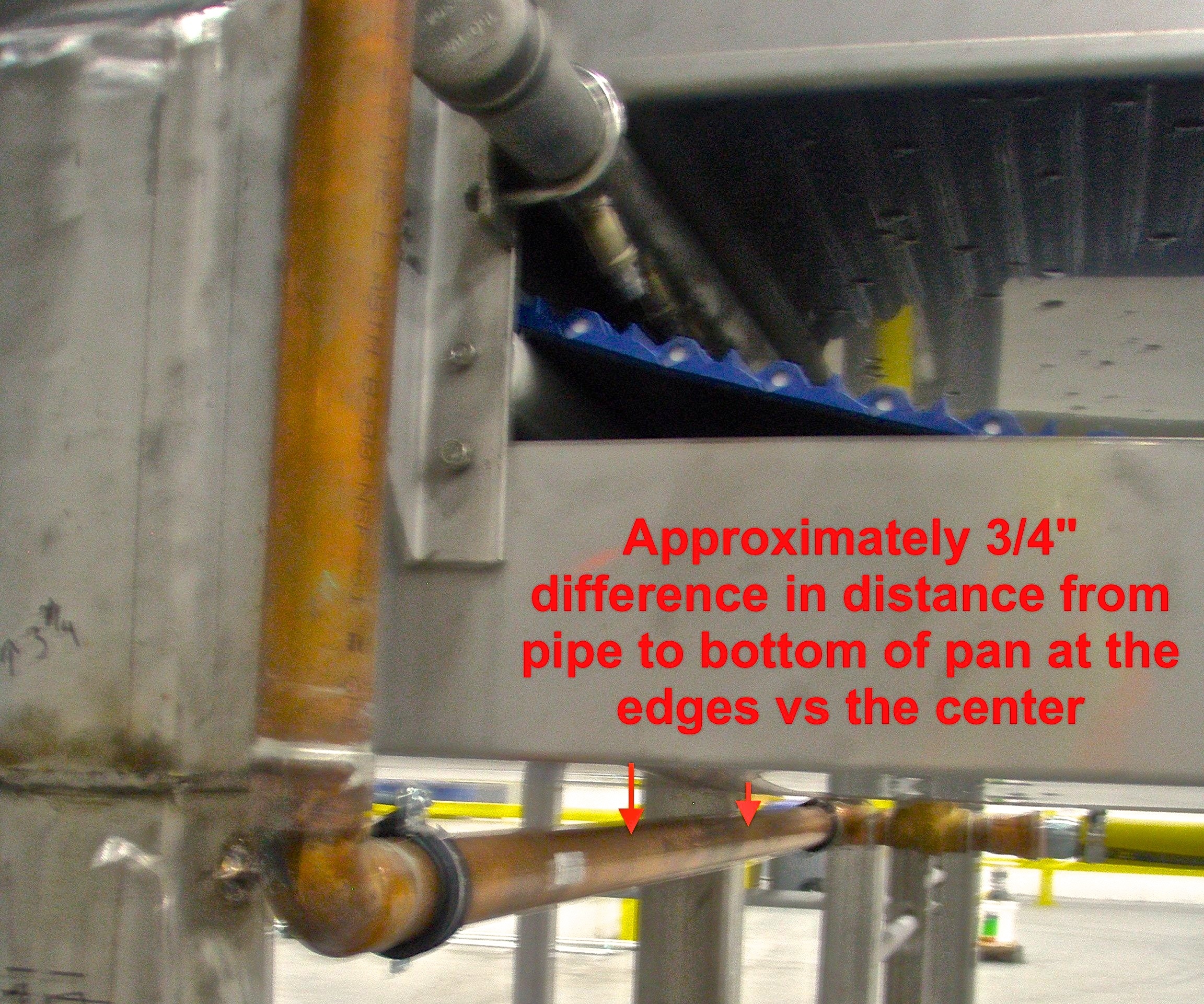

The plant wanted to ensure sufficient headroom under the belt systems to ease cleaning, so installed them without providing enough slope to drain the washing water which is constantly flowing over the fruit during operation. So the water built up and the weight bent the pans inward rubbing on the belts.

Improving and Franchising Jib Set Sailing Club

A mystery that took significantly more work to investigate and solve was how it might be possible to franchise a sailing club called Jib Set; a subsidiary of Cooper Boating.

It turns out that the first part was trying to make the club profitable. This took some time to untangle from the various businesses that its parent company is engaged in. Such as:

- Selling sailing training courses to members.

- Selling the club 6 boats that the parent company was manufacturing and marketing. For any other club in the world there would be no reason for them to buy something that costs twice as much as the market price.

- The general disorder of the club: poor control systems were unable to convince more people to become paying members, or pay as guests of other members.

The simplest beginning to a solution was to improve the club policies and control systems with updated web-based tools for tracking and controlling member use and payments. I specified the necessary parts of a new online presence and then found service providers to bid on building it. After making those introductions and reviewing those bids I left the project in the hands of the business owner. It is unclear exactly how the parent company decided to proceed with the project.

To date there has been no move to franchise the club. This lack of interest is probably due to continuing difficulties in making the club break even. This could be solved by investment in modern tablet and smartphone based solutions to streamline payment processing, maintenance and training. Such a system, as well as associated processes and training would be the most valuable part the franchiser would be able to sell to franchisee clubs.